Search This Supplers Products:Filling LinePacking MachineShrinking MachineLabelling MachineSealing MachineCapping Machine

Hot sale Automatic Lubricants filling machines line

- group name

- Lubricating oil filling line

- Min Order

- 1 piece

- brand name

- DONGTAI

- model

- FPML

- Nearest port for product export

- Qingdao, Dalian, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C

- update time

- Mon, 10 Dec 2018 16:08:48 GMT

Paramtents

Filling nozzles 8

Filling speed 1500-2000 (barrels / hour)

Filling capacity 1-5L

Filling accuracy ± ≤ 0.1% FS

Whole line consumption about 100L/Min

The equipment noise less than 50D

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

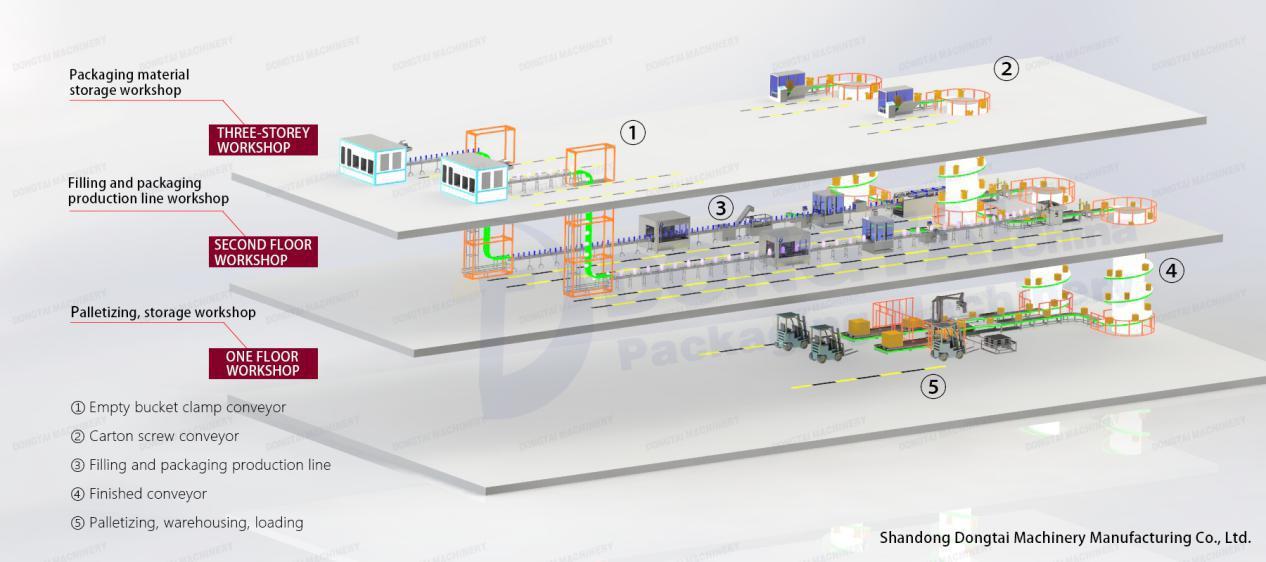

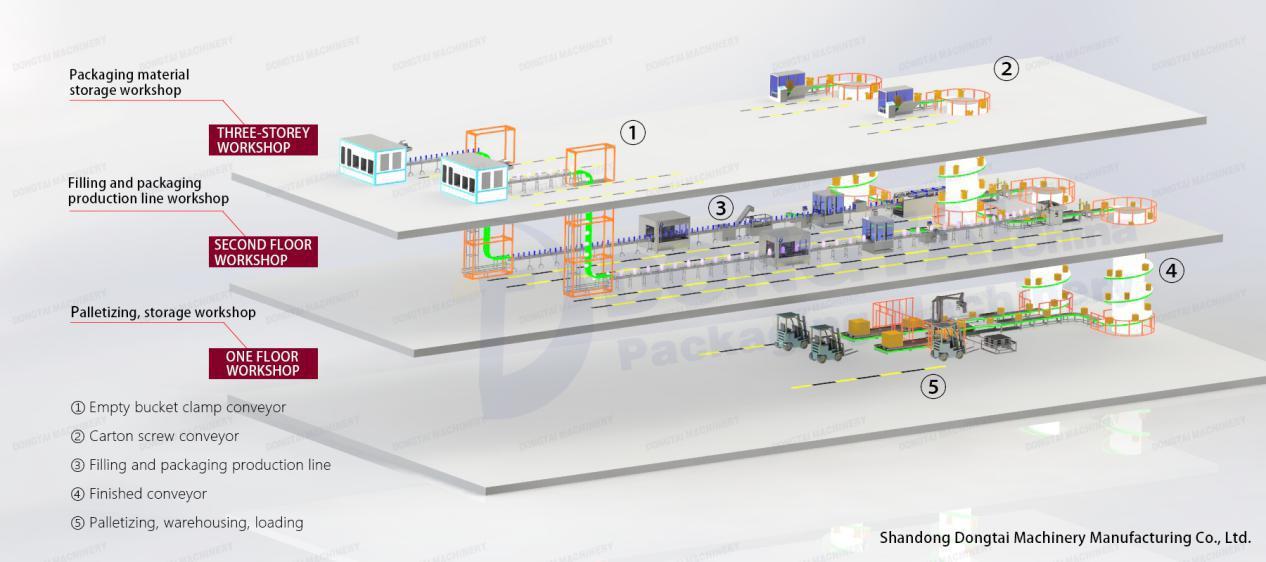

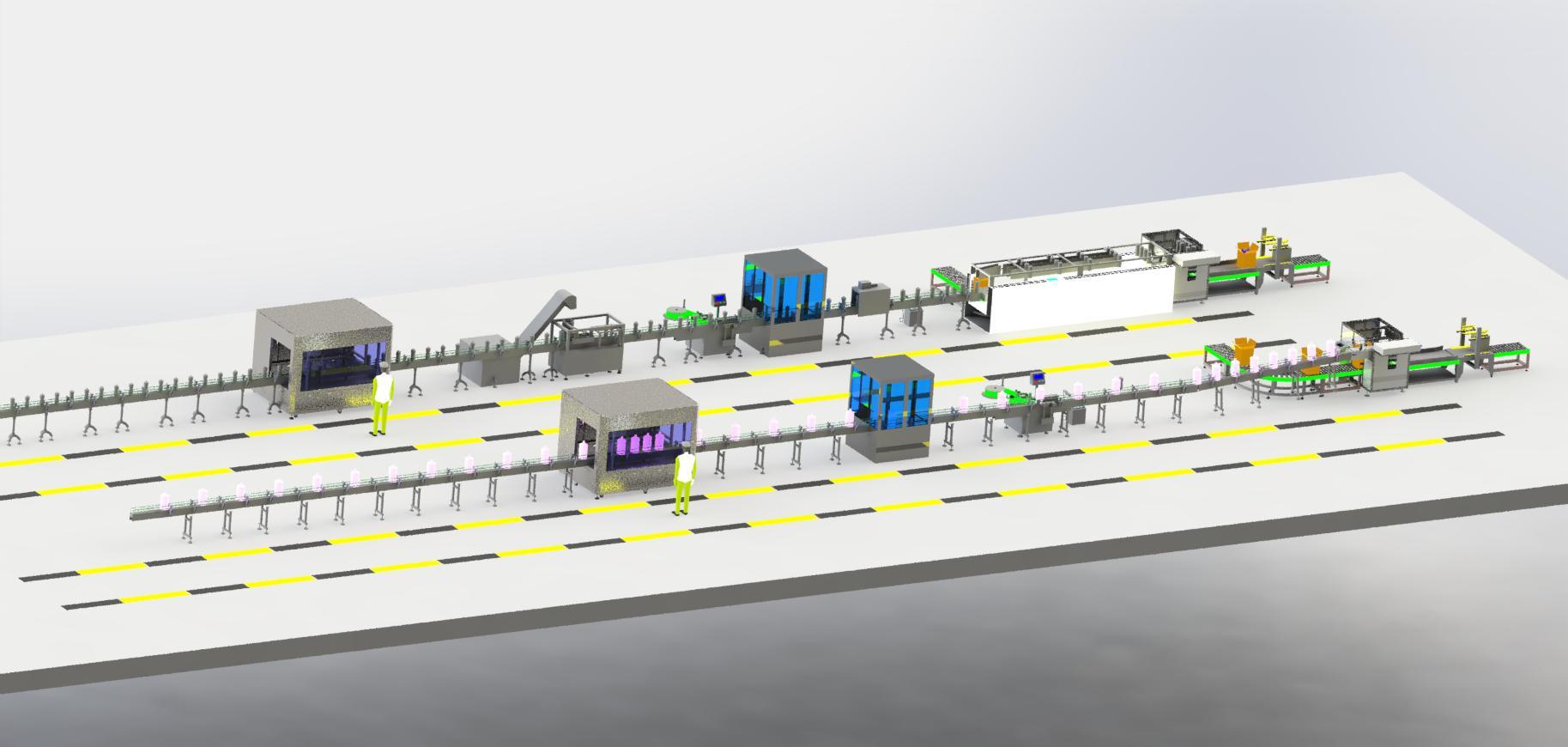

The filling line equipment has the characteristics of stable, easy operation, high cost performance and high automation. Compared with the same kind of product, it has a longer service life, a complete set of ability, and a reasonable design of the whole line. Equipped with coordinated photoelectric and whole line interlocking devices, the whole line needs only 2-4 workers for operating. The technology used is the leading level in today's industry. The whole line of filling equipment meets the needs of production, unmanned and integrated production.

Filling nozzels |

8 |

||

Filling speed |

1500-2000 (barrels / hour) |

||

Filling capacity |

1-5L |

||

Filling accuracy | ± ≤ 0.1% FS | ||

Power supply |

220/380V3 phase +Earth Wire, 50 Hz |

||

Number of workers | 3-5 people | ||

Whole line consumption | about 100L/Min | ||

The equipment noise | less than 50D |

The machine is suitable for sorting and feeding of various plastic buckets, and has stable performance. It can be used together with the automatic packaging line to save labor and increase production efficiency. Put the whole barrel flat on the platform, and push the rod automatically to push the belt into the barrel. Orderly, do not hurt the barrel. It is composed of PLC control electric part, photoelectric sensor and frequency conversion governor. It has high integration level, strong control ability, reliable operation and can be controlled in conjunction with filling equipment.

Overall size |

2000×1200×1000mm |

|

Production capacity |

≤ 3000 bottles/hour |

|

Applicable specifications |

1-4Lbottle |

|

Equipped with power supply |

220V 50Hz 1.5KW |

|

weight |

300kg |

|

This machine is a flow meter filling machine with high filling accuracy. It applies to 1-5L liquid for filling.It uses filling bulkhead of preventing leaking and wire drawing, filling up and down system of preventing high foam products, assuring the lip orientation and automatic control system. The tank controls material level automatically ,feeding the material is also automatic.The tank adopts the pressurized design that will improve the speed of the blanking. Combine with the mechanotronics protecting device, if the machine has any abnormal information ,it will stop and alarm automatically. The touch screen will appear the detail parts which is abnormal. It is produced with the GMP standards, safety, environmental , hygienism, beautiful and adapt to different kinds of work place.

Filling nozzles |

8 |

|

Filling capacity |

1-5L |

|

Filling type |

Flow meter |

|

Filling speed |

1500-2000 (barrels / hour)-4L |

|

Filling accuarcy |

± ≤ 0.1% FS |

|

Power supply |

220/380V 3 phase +Earth Wire, 50 Hz |

|

Pressure |

0.5-1 .0 Mpa |

|

Power | 2.5kw | |

Humidity | <98 % | |

Ambient temperature | 0~40℃ | |

Size | 1800*1200*1780mm | |

weight | 300KG | |

machine adopt tracking apparatus and private servo displacement system , includes cap sorting, hanging and capping in one unit, capping head and bottle running synchronous, capping heads adopts servo controlled torsion capping, no harm to bottles and caps. Whole machine advanced structure, smooth operation, low noise, wide range of application, high production speed.PLC memory formula, one key call parameter, External frame of security protection. Automatic lubrication function long life time.

Capping heads |

1 |

|

Capping capacity |

≤2000 bottles/hour |

|

Bottle size |

D 30-110mm H 50-250MM |

|

Cap size |

H 10-35MM 18-80MM |

|

Voltage |

380V 50Hz |

|

Power |

5.5kw |

|

Air pressure |

0.55-0.65MPa |

|

Production efficiency | ≥98% | |

packing pass rate | ≥99.9 | |

Weight | 900kg | |

Size | 1700×1300×2200mm | |

Type of Equipment: automatic on-line high-speed sealing machine

Control System: transistors modular digital integrated circuit control ground

Cooling System: Dual fan, double radiator water cooling system forced circulation

sealing effect: the seal intact, one hundred percent. Even a small amount of liquid bottle leaving traces, does not affect the sealing effect.

Power |

2800W |

|

Voltage |

AC 220V / 50Hz 13A |

|

Sealing diameter |

φ16-80mm |

|

Sealing speed |

3-12m / min, 40-150 bottles (φ30mmPE bottle 120 bottles / min) |

|

Container height |

30-600mm special requirements can be customized |

|

Sensor size |

850 × 120 × 900mm |

|

This machine is widely used in food, toys, daily chemical, electronics, medicine, metal, plastic, printing and other industries; such as flat shampoo bottles, flat medicine bottles and so on. It adopts standard PLC, touch screen, standard sensor electronic control system, human-computer interface in Chinese and English notes and improve the function of fault tips, operational guidance functions, troubleshooting instructions; easy to use and easy maintenance; no product non-labeling, non-sticker auto-correction and automatic detection function. It can be also matched with batch coder or printer coder function.

Power |

3KW |

|

Voltage |

380V,50HZ |

|

Speed |

30-50bottle/min |

|

label specifications |

W.30~100mm H.30~160mm |

|

Bottle size |

thickness 15-120mm, Height 90-300mm |

|

Labeling accuracy |

±1.0mm |

|

Width for label |

10-150mm |

|

Height for conveyor | 840-900mm | |

Size | 2400mm×1500mm×1600mm | |

6.Videojet 630S Imported computer ink jet printer

Printing line |

1-3 |

|

line printing,speed |

492fpm(150m/min) |

|

Sign Line |

5x5,5x7,7x9,12x16,16X16 |

|

Double /Three line |

5x5,5x7 |

|

Character height |

2mm 一 7.5mm |

|

Printing distance |

Range:5mm-15mm Best:12mm |

|

Keyboard |

Contsist of 72 Character |

|

Display | 320x240 Bright blue backlit 5.7 "LCD Display WYSIWYG editing screen information | |

Customer logo / design | Can be created for each user on a computer or printer | |

Character Set | English, Simplified Chinese | |

Language and interface options | English, Simplified Chinese | |

Information Storage | 50 complex information. Unlimited storage using USB. Standard USB with logo and memory backup features | |

Protection class | IP43: Stainless steel cabinet | |

Sprinkler head |

Heating nozzle |

|

Diameter |

1.6 "(41.3mm) |

|

Length |

9.5 "(241.0mm) |

|

Throat Ultra-flexible |

Length: 6.56 '(2m) Diameter: 0.91 "(23mm) bend radius: 3.O" (76.2mm) |

|

Smart ink cartridges |

0.793qt (750ml) |

|

Solvent intelligent cartridge | 0.793qt (750ml) | |

temperature range | 410F to 1130F (5 ℃ -45 ℃) | |

Claim | Nominal power 100-120 / 200-240VAC. 50 / 60Hz. 90 | |

Weighs | No packaging and neck weight: 35.28lbs (16kg). | |

Options | Electric eye interface shaft encoder interface 9.8 ft (3m) hose 60 or 70 micron nozzle | |

7.Opening-packing-sealing Integrated Machine

The machine is new type of automated packaging equipment,reached and designed on the basis of foreign advanced technology. The machine has distinctive features compared with the similar packaging way. The vast majority of regular bottled, boxed, block and other products, widely use corrugated carton packaging in the present domestic production, has been accepted by the public.It can finish at one time, reduce the cost of equipment and the space of equipment and raw materials and all levels of transportation contradiction. The appearance of the packaging is beautiful and smooth;It is tight and firm after wrapping.Application of unpacking-packing-sealing integrated machine, reduce labor intensity, labor resources and production process, will upgrade the traditional packaging way and the inevitable trend of development.

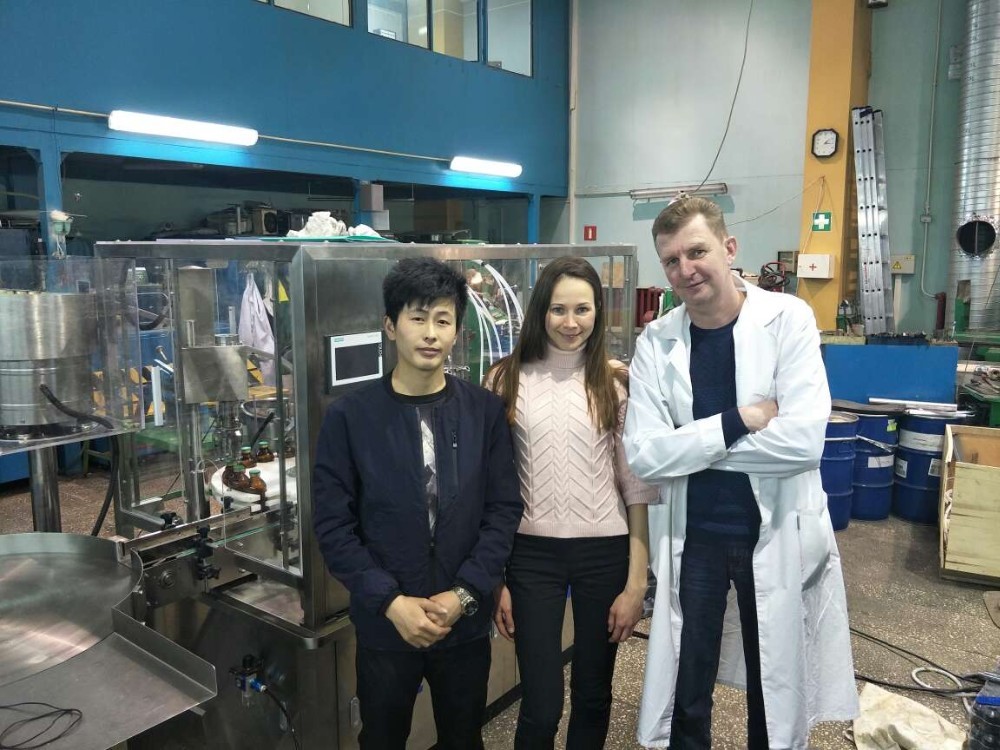

In order to ensure product quality, all suppliers of raw materials, electrical components, and industrial automation that strictly control all aspects of circulation are from well-known brands at home and abroad. They must be strictly inspected by quality inspectors before entering the warehouse. Use, product production is completed, from the assembly plant into the commissioning workshop, after a number of rounds of precision and speed test, after commissioning can be allowed to leave the factory.

Q: What's the insurance of after-sale service after purchase?

A: All our products, will be totally tested by QC department before delivery, with strict quality control process. The product is cost-effective during use, stable and reliable.

One year warranty service for all machine, please feel free to contact us if you have any questions.

Q: When the machine arrives at the work site, is it easy to install? How to solve the problem of quick installation and use?

A: All machine model with installation video, to show the installation process more intuitively, and we will provide remote video technical support to solve your doubts and ensure that your installation is correct.

Install video URL: https://..........com/groups/1644623782523083/

https://..........com/channel/UC_wUu5QTxgZsfGRzgxxK29w?view_as=subscriber

(FOLLOW US ON YOUTUBE, TO SEE MORE ABOUT US)

After-sales appointment installation service phone :

+8618560751875 86-531-88168830 engineer Zhang

Q: During the use of the machine, how to get after-sale service?

A: We have professional foreign installation and commissioning engineers, which have many years of experience in foreign debugging with deeply recognized by customers. We will provide on-site installation and commissioning services for foreign customers, and we will guide your workers directly.

Q: Will the accessories change frequently with machine ?

A: The service life of the accessories is related to the daily maintenance. When ordering, we will give you free wearing parts and provide you with daily maintenance strategies.

1. Cover by PVC film + fumigated wooden case;

2. Wooden case suitable for long distance ocean shipping.

Shandong Dongtai Machinery Manufacturing Co., Ltd. was established in 2008 and is located in Lingang Economic Development Zone, Jinan, China. The company is committed to the design, manufacture and sales of packaging machinery and equipment. It is a high-tech enterprise specializing in the research and development, production, sales and service of automated packaging machinery equipment. The company has professional technicians, engineers and sales and after-sales service personnel, forming a team of high quality, young, highly innovative spirit.