Search This Supplers Products:Filling LinePacking MachineShrinking MachineLabelling MachineSealing MachineCapping Machine

SYFM-12 Automatic edible oil filling machine

- group name

- automatic oil filling machine

- Min Order

- 1 set

- brand name

- DONGTAI

- model

- SYFM-12

- Nearest port for product export

- Qingdao, Dalian, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C

- update time

- Fri, 10 Apr 2020 14:09:49 GMT

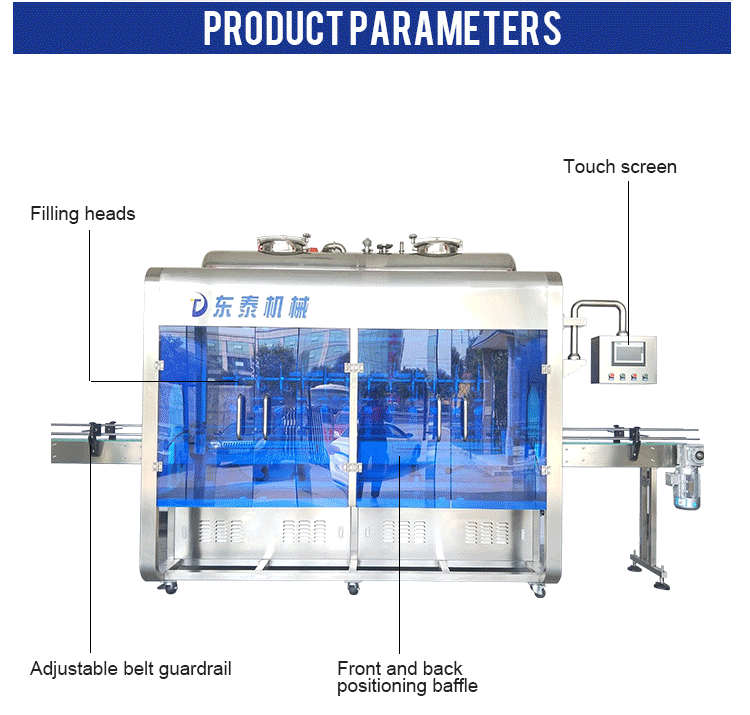

Paramtents

Filling volume 1L-5L

Filling speed 1800-2200 bottles/hour

Filling accuracy ±0.1%

Current 3A

Voltage 380V 50/60Hz

Power 2.5kw

Air perssure 0.5-0.7MPa

Size 2450*1750*2400(mm)

Packging & Delivery

-

Min Order1 set

Briefing

Detailed

SYFM-12 Automatic edible oil filling machine

Product introduce:

This series of automatic grease filling machine adopts flowmeter type metering filling

principle and many patent certifications. It is suitable for pumpkin seed oil, hazelnut oil,

peony seed oil, sesame oil and walnut oil of various specifications (1-5 liters). Camellia oil,

linseed oil, cottonseed oil, olive oil, soybean oil, corn oil, rapeseed oil and other edible oils.

The equipment adopts high-precision rotary encoder to ensure the filling accuracy of 1‰,

and the filling speed is improved by 20%-35% while ensuring the filling accuracy. The

operation is simple, the maintenance is convenient, the labor cost is saved, and the

production is saved. higher efficiency.

Features:

The filling machine adopts the utility model patent certified by the State Intellectual

Property Office: single-head single-pump single-frequency filling control system; patent

certificate number: ZL 20132 0356808.4; patent certification time is November 2013;

(1) Each filling head is a set of independently operable control systems. Customers can

flexibly set the number of filling heads to be used according to their own production

volume. Each filling head does not affect each other and does not affect the operation of

the filling of the whole machine because one of the filling heads requires maintenance.

(Any filling head can be closed with one button, and the number of filling heads left after

the program is closed by default will continue to work)

(2) The pipeline pressure is more stable during the filling process, and the metering error

is too large or splashed due to the traditional one-pump multi-head flow type and other

metering methods because the final pressure is concentrated to close the filling head. The

single-head single-pump single-frequency conversion method guarantees a filling

accuracy of 1‰ and increases the filling speed by 20%-35%.

(3) Single-head single-pump single-frequency conversion control, volume and quality can

be freely converted in two metering modes, and filling adjustment is convenient and quick.