Search This Supplers Products:Filling LinePacking MachineShrinking MachineLabelling MachineSealing MachineCapping Machine

Alcohol hand sanitizer filling machine

- group name

- automatic liquid filling machine

- Min Order

- 1 piece

- brand name

- DONGTAI

- Nearest port for product export

- Qingdao, Dalian, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C

- update time

- Sat, 30 Jan 2021 14:00:25 GMT

Packging & Delivery

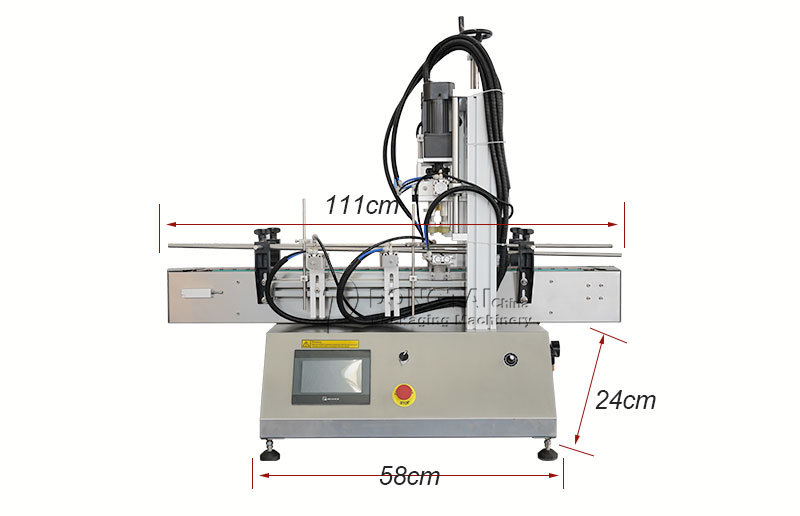

- 111cm x65cm x42cm

-

Min Order1 piece

Briefing

The hand sanitizer filling machine, as its name implies, is a filling machine

Detailed

Alcohol hand sanitizer filling machine

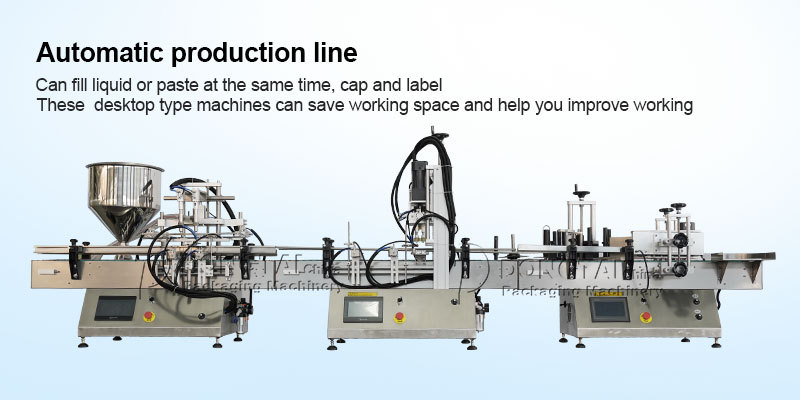

The hand sanitizer filling machine, as its name implies, is a filling machine used to fill paste, viscous liquid, and viscous fluid. The hand sanitizer filling machine generally uses compressed air as the power, which is easy to operate and simple in structure.

Hand sanitizer filling machine is our company's filling and sealing equipment series, which is suitable for filling various round, special-shaped bottles and small bottles. Hand sanitizer filling machine It is mainly suitable for filling various injections, disinfectants, oral liquids and syrups, alcohol and various medical liquids. It is widely used in the fields of food, pharmacy, chemical industry and scientific research. .

|

name

|

Liquid filling machine

|

Power supply | 220 / 110V 50/60 Hz |

Filling range | 5-60ml |

Power | 10 watts |

Pressure | 0.4-0.6 MPa |

Filling speed | 30-50 bottles/min |

|

Filling accuracy

|

≤±1%

|

|

Net weight

|

37kg

|

|

Filling volume

|

3-1000ml(220V)3-500ml(110V)since the power of 110v mechine is not lange, so we recommend

|

easy to operate

Liquid filling machine It is easy to operate, and the pneumatic parts adopt pneumatic components from Germany FESTO and Taiwan AirTac.

The structure is simpler and more reasonable, the accuracy is high, and the operation is easier.

PLC and color touch screen control

Imported programmable controller PLC and color touch screen control, the Liquid filling machine control system is more accurate and reliable. More than 20 recipe parameters can be stored. When customers fill materials with different specifications and different densities, they can preset and store parameters, and switch with one key.

No drip filling head

The filling volume and filling speed can be adjusted arbitrarily. The filling head adopts anti-drawing and lifting filling device.Liquid filling machine The filling head and cylinder of the Liquid filling machine adopt a split mechanism, and the accessories use standard parts, which are easy to replace and maintain.

316 stainless steel

The Liquid filling machine material contact parts are made of 316L stainless steel, which meets GMP requirements.

The filling valve is controlled by a solenoid valve, and the filling accuracy is higher.

|

Working Voltage

|

AC220V/110V 50- 60HZ

|

Bottle Height | 60-270mm |

Bottle Caps Diameter | 18 -70mm |

Working Speed | 20- 40 bottles/minute(depending on bottle and cps) |

Working Pressure | 0.4-0.6 MPa |

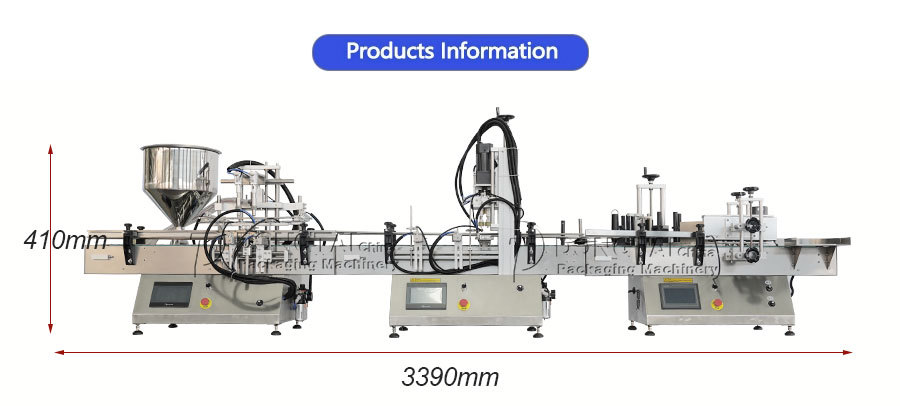

Machine Size | 1120* 580* 1110mm |

Conveyor Length | 1110mm |

Net Weight | 65kg |

|

Package Weight

|

97.5kg

|

|

Package Size

|

1160*610*1140mm

|

|

Size Of Air Compressor Connector

|

OD 8mm

|

|

Voltage

|

110V-60HZ / 220V-50HZ

|

|

Working speed

|

20-50ottles/min

|

|

Suitable labeling size

|

15-140mm (W) X 25 300mm (L)

|

Roll inside diameter | φ76mm |

Roll outside diameter | φ350mm |

Suitable bottle diameter | ≤100mm |

Net weight | 95.5kg |

Package Size | 1270*530*820mm |

Gross weight | 125kg |

|

Size of air compressor connector

|

OD 8mm

|