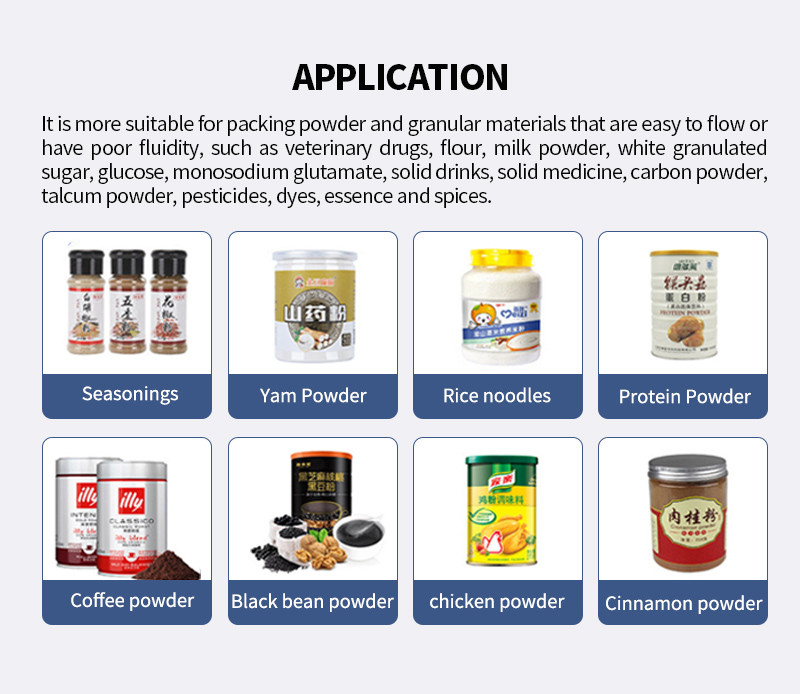

The filling sealing machine automatic has a wide range of applications: powder and granular materials with certain fluidity can be packaged. Photoelectric switch control, only need manual bagging. The pocket is clean and easy to seal. The parts in contact with the materials are made of stainless steel, which is easy to clean and prevent cross contamination

Search This Supplers Products:Filling LinePacking MachineShrinking MachineLabelling MachineSealing MachineCapping Machine

automatic 1kg milk papaya spice powder seasoning bottle detergent filling packing machine

- group name

- automatic powder filling machine

- Min Order

- 1 piece

- brand name

- DONGTAI

- Nearest port for product export

- Qingdao, Dalian, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C

- update time

- Thu, 11 Jul 2024 15:14:42 GMT

Packging & Delivery

-

Min Order1 piece

Briefing

automatic 1kg milk papaya spice powder seasoning bottle detergent filling packing machine

Detailed

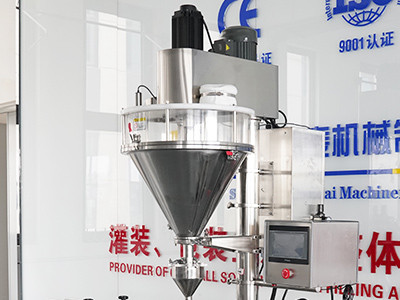

The semi automatic filling machine is an economical powder and small particle automatic filling machine, which can complete the automatic positioning, filling and metering of the bottle. It consists of a filling head, a connecting belt and a positioning device. Or stepping) motor, PLC and touch screen control, easy operation and high stability. It can be combined with bottle opener, capping machine and labeling machine to form a complete filling line.

Adopting international and domestic advanced technology, PLC and touch screen control, the semi automatic powder filling machine is easy to operate, high stability, optical fiber sensor control, microcomputer text display and touch manual interface operation.

Servo (or stepping) motor drives the screw, accurate positioning, speed setting, replacement of screw attachments, suitable for various materials from ultra-fine powder to small particles. After the material flow, the filling machine powder is equipped with a centrifugal device to ensure accuracy. Dust material outlet can adopt dust suction device to absorb spray-proof dust.